Osprey – Nearshore Construction of Seacombe Ferry Terminal

We’re proud of the work our Marine Engineering, Logistics, and Heavy Lift teams have been doing to support the Seacombe Ferry Terminal project. The original structure at the Seacombe Ferry Terminal dates back to the 1870s. Over time, the infrastructure itself had suffered in the elements, and the linkspan bridges had now reached the end of their operational lifetime – they all needed to be removed and replaced.

While the linkspan bridges need to be moved, our client was tasked with executing major refurbishment works on the landing stage, including upgrading the mooring bollards and installing new powered gangways. This is all part of a major investment to keep the services running at Seacombe for many years to come.

Cllr Liam Robinson, Transport and Air Quality Portfolio Holder for the Liverpool City Region Combined Authority: “The installation of these new linkspan bridges marks a major milestone in this significant investment at Seacombe Ferry Terminal by the Combined Authority. The Mersey Ferries are an important part of our cultural identity and these works will make sure that they continue to run from Seacombe for many years to come.”

Planning and delivery

Due to the age of the structures and the limited availability of historical documents showing how they were built, and how they worked, Osprey supported their client for 18 months in the lead up to the project with marine engineering, naval architecture and project management expertise, developing comprehensive method statements, lift plans, risk assessments and a detailed project schedule for the execution of all tasks within our scope.

This is Osprey’s advantage: we have the marine, heavy lift and civil engineering expertise in-house, combined, with experience from multiple sectors allowing us to provide bespoke, turn-key solutions to our clients’ challenges.

- Co-ordinated heavy lifting and marine asset removal

- 18 months of expert, marine engineering support

- An adjustable mooring, coping with tidal flows

- Mooring studies supporting infrastructure removal

- Unique project solution with a floating crane barge

Prior to commencing the deconstruct phase of the project, Osprey engineered and delivered an adjustable mooring system that would maintain the position of the ferry terminal pontoon in the River Mersey, for the duration between removal and reinstatement of the bridges and restraining booms. A mooring study explored how the pontoon would behave when we removed sections of the bridge, and what would need implementing to keep our vessels in place and provide moorings for our vessels. We had to contend with limited space, shallow water, vessels transiting the river, tides, and a significant swell.

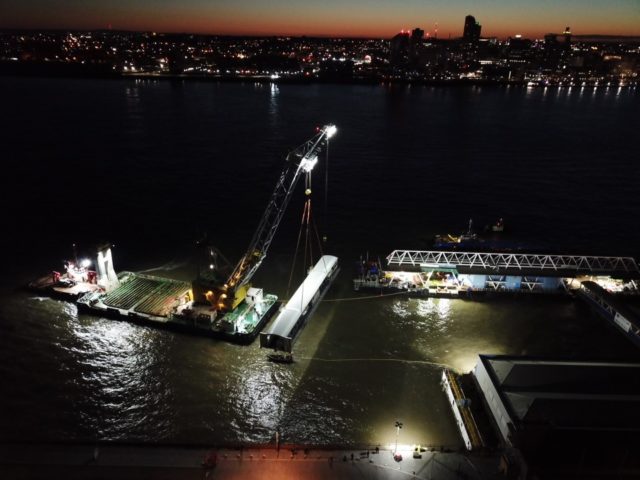

The deconstruction phase took place in July, as we carried out five co-ordinated lifts over five days, lifting out the restraining booms and old linkspans. This narrow window had to take the Mersey’s significant tidal flow into consideration, meaning our teams worked into the night for some of the operation. We then transported these over-sized components away from the site, ready for disassembly or refurbishment.

Over a four-day period, the new north and south linkspan bridges – weighing in excess of 125 tonnes each and refurbished north and south booms – 50 tonnes each, were moved into place on the quayside using a small fleet of SPMTs and loaded to the barge with our LG1550 Crane. The barge was then towed to site in readiness for the marine lifting operations to take place. This marine lift was unique: it involved using a floating crane barge to locate and install each bridge section, using a bespoke mooring system to align the pieces perfectly in position between the shoreside terminal and floating pontoon. We also consulted on the temporary locating structure that was needed to guide those bridge sections into place.

The tidal phases here only provided short windows for operations, and it was essential to plan everything down to the last detail: the timing for every phase of the work was critical. The River Mersey has a fast current and the second-highest tidal range in the UK, and the strong swell made for a challenging first lift of the bridge sections in the dark. Even for our crew transfers and safety boats, the swell and the current presented an interesting challenge.

We wanted to ensure our lift work supported the project team’s aspirations for minimum disruption, as much as possible. The installation of new sections for the reconstruction element of the project was completed in October 2021.

Joe Wardle – our Project Manager on the Seacombe Ferry Terminal project: “This project has shown what team work and having the right people with the right skills on the job can achieve. The Osprey team worked collaboratively with all involved to ensure the job was completed safely and successfully for our client.”

This project highlighted how valuable our team’s marine engineering and naval architects’ experience is, as we were able to help everyone else involved to find the safest, most practical solution in this challenging environment – site meetings with our client, end clients, pilots, vessel captains, partners and third parties… getting everyone’s input, making sure every aspect of the project was conducted as safely as possible.

Darren Warner – our Lift Supervisor for this project: “In 26yrs of doing this job and working all over the world, this is definitely one of my top five jobs!”

Neil Schofield – our Chief Operating Officer: “We are immensely proud to have played such a big part in this project, working alongside Sisk to firstly deconstruct the original linkspans and booms and then ensure the highly challenging reconstruction phase went smoothly. The project certainly had its challenges, but our collaborative way of working meant we could overcome all the obstacles and challenges for our client, John Sisk and Son. I want to thank everyone in our teams for their hard work, long hours and dedication during this project.”

While the actual ferry terminal will stay closed until Spring 2022, the new landing stage at the Seacombe Ferry terminal should have a sustainable operation window of least 25 years before any major future maintenance is needed again – when Osprey will, of course, be ready to support the team again.

Robin Metcalf, Contracts Manager, SISK: “John Sisk & Son’s UK Civils Business contracted Osprey to carry out the marine logistics for the Seacombe Ferry Terminal project. This was a complex project, excellently managed by Osprey, with the result that everything was delivered to programme and on budget.”

Dave Hill, Regional Director, SISK: “Osprey worked closely with Sisk during the tender phase of the Seacombe Ferry Terminal to develop a complex methodology for removing the existing linkspans and subsequent installation of the new linkspan structures. Following the successful award of the contract, we worked together during the ECI phase to further develop the detail from the tender. The planning around these works was excellent and this resulted in all lifts being carried out successfully and exactly in line with our programme. When we had to postpone the installation lifts, Osprey worked hard to reschedule all the resources to meet the revised programme. The River Mersey presents a challenging working environment and Osprey were able to use their expertise to overcome these challenges.”